Most Popular Products

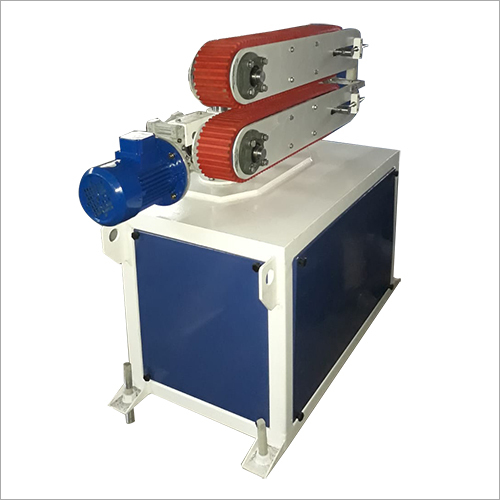

Twin Screw Extruder

Twin Screw Extruder Specification

- Product Type

- Extruder Machine

- General Use

- Plastic Processing

- Material

- Stainless Steel

- Type

- Twin Screw Extruder

- Capacity

- 150-200 Kg/hr

- Weight (kg)

- 2500 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Controlled

- Screw Design

- Parallel Co-rotating

- Screw Diameter

- 52 mm

- Voltage

- 380 V

- Motor

- 37 kW

- Heating Power

- 18 kW

- Dimension (L*W*H)

- 4200 mm x 1200 mm x 2200 mm

- Color

- Blue-Grey

- Lubrication System

- Automatic Centralized Lubrication

- Display Interface

- Touch Screen HMI

- Barrel Material

- Nitrided Alloy Steel

- Application

- Compounding, Masterbatch, Filler, Engineering Plastics

- Safety Features

- Overload Protection, Emergency Stop

- Feeding Method

- Forced Feeder

- Max. Screw Speed

- 600 rpm

- Cooling Method

- Water Cooling

- Noise Level

- 80 dB

Twin Screw Extruder Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Months

About Twin Screw Extruder

|

Brand |

VF |

|

Automation Grade |

Automatic |

|

Phase |

Single |

|

Material |

Mild Steel |

|

Power Source |

Electric |

|

Voltage |

220 V AC |

|

Frequency |

50 Hz |

We have an eminent name for offering a vast array of Twin Screw Extruder. This product is manufactured using only quality tested materials.

Performance Features:

- Latest generation Machine with High Performance.

- Low power consumption and energy saving with Heavy Output.

- Achieve uniform pumping.

- Two Piece Barrel Design For Low Maintenance.

- Front Side H.S.S Sleeve for Easy Screw Barrel Maintenance.

- Tungsten Coating for Wear & Tear.

- Internal Oil Circulation with Cooling System for Gear Box.

- Synchronization of drive of Extruder with Feeder and Traction Unit to reduce wastage and

- Fast Production.

- S.S -304 Vertical feeder for easy aclaption of different bulk density of materials.

- Gentle plasticizing, great melt quality with Material Mixing Formulation.

- Japanes PI D Control type Temperature Controllers Processor friendly.

- Raw-materials & brought out items from the world-class quality makers.

- Maintenance-free screw cooling system.

- Efficient barrel cooling system.

- AC motors with optimal degree of efficiency.

- Custom-made anti-wear protection made. of tungsten carbide and

- chrome combined with top-quality nitride surfaces.

- Output ranges maximized through. optimized screw geometries.

- Special power saving system with details.

- Easy handling through intelligent machine design.

- Easy and Extra Power Saving Systems.

- PLC controls on request.

- 10% to 15% Heating Power Saving Systems In PLC Bese Controll.

- Including Thick Thin Device for Casing and Column Pipe.

- High Alert System for Heating Tripping and Motors Tripping.

- Easy Operating System.

- Cold by pass for screat barrel safety.

- Zero start system.

- Yaskuwa drives with heavy dust proof secours.

- Easy plug & play systems.

- All standard controllers.

Advanced Technology for Consistent Processing

This Twin Screw Extruder integrates state-of-the-art features, such as touch screen interfaces and PLC-controlled systems, for seamless, efficient, and reliable operation. Its computerized automation ensures steady performance across various plastic compounding tasks.

Superior Construction for Longevity

Manufactured from nitrided alloy steel and stainless steel components, the extruder offers lasting durability and resistance to wear, making it a solid investment for manufacturers looking for high throughput and minimal downtime.

User-Friendly and Safe Operation

Designed with operator safety in mind, the machine includes comprehensive features like an automatic lubrication system, overload protection, and emergency stop. The intuitive touch-screen HMI makes monitoring and control straightforward for all users.

FAQs of Twin Screw Extruder:

Q: How does the forced feeder improve material input in the Twin Screw Extruder?

A: The forced feeder ensures a consistent and controlled feeding of raw materials, preventing blockages and optimizing the flow into the extruder for smoother processing and better quality outputs.Q: What applications is this extruder suitable for?

A: This Twin Screw Extruder is ideal for compounding, masterbatch production, filler processing, and engineering plastics, catering to diverse needs in the plastic processing industry.Q: When should the water cooling system be activated during operation?

A: The water cooling system is automatically engaged during extrusion to maintain optimum processing temperatures, prevent overheating, and ensure consistent product quality.Q: Where can this machine be installed and used?

A: With a robust design and moderate noise output, the extruder is suitable for installation in factories, manufacturing facilities, and R&D centers focused on plastics, across India and worldwide.Q: What is the process of maintaining the extruders lubrication system?

A: The extruder is fitted with an automatic centralized lubrication system that minimizes manual intervention. Regular checks on lubricant levels and scheduled system reviews ensure optimal performance.Q: How does the touch screen HMI benefit operators?

A: The touch screen HMI simplifies control by providing a user-friendly interface for setting parameters, monitoring performance, and troubleshooting, reducing operator workload and enhancing efficiency.Q: What are the safety features included with this Twin Screw Extruder?

A: The extruder incorporates overload protection and an emergency stop, safeguarding both the operator and equipment during unexpected events or operational faults.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Twin Screw Extruder Category

UPVC Twin Screw Extruder

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Material : Other

Voltage : 220 to 415 Volt (v)

Computerized : Yes

|

VITAL FORCE ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |