Most Popular Products

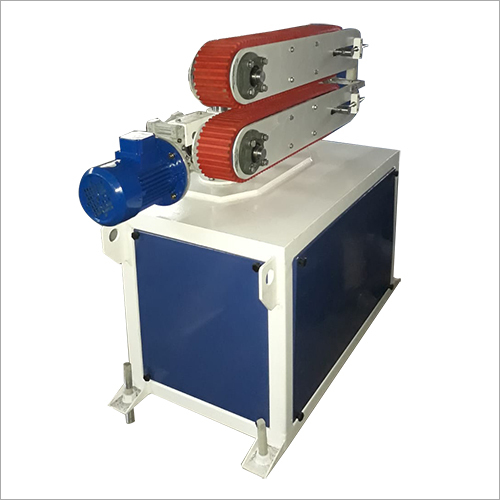

Twin Screw Barrel

Twin Screw Barrel Specification

- Power Source

- Electric

- Application

- Plastic Extrusion, Rubber Extrusion, Pelletizing, Compounding

- Cutting Speed

- Adjustable

- Noise Level

- Low

- Tool Type

- Extruder Screw Barrel

- Spindle Speed

- Up to 600 rpm

- Product Type

- Twin Screw Barrel

- Material

- Alloy Steel/Nitrided Steel/Bimetallic

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC/Manual

- Drive Type

- Electric

- Voltage

- 220-440 V

- Weight (kg)

- 300-800 kg (varies by model)

- Dimension (L*W*H)

- Customized (e.g., 1000-6000 mm length)

- Capacity

- 50-500 kg/hr

- Feature

- Corrosion and wear resistance, High Strength, Long service life

- Color

- Metallic Grey/Silver

About Twin Screw Barrel

We are one of the leading manufacturers and suppliers of Twin Screw Barrel that is fabricated by using highly tensile alloyed steel that makes it capable to bear harsh working conditions produced during the making of PVC pipes. It is provided with a shiny galvanized coat that acts as a protective barrier to prevent damages from highly corrosive environment. The offered Twin Screw Barrel comes in various sizes as per the machines in which it is going to be installed.

Custom Engineered for Diverse Industrial Applications

Our twin screw barrels are precisely manufactured to meet the demanding needs of plastic and rubber extrusion industries. Available with water or air cooling options and various control systems, these barrels ensure optimal processing conditions. With adjustable cutting speed, low noise output, and high spindle speed capabilities, they offer versatility for both compounding and pelletizing. Every barrel can be tailored for specific project requirements, from length to diameter and mounting configuration, offering flexibility across different production lines.

Advanced Surface Treatments for Maximum Durability

We utilize nitriding, hard chrome plating, and bimetallic coating processes to achieve a robust wear- and corrosion-resistant surface. This innovative engineering, combined with high-grade alloy and nitrided steel, lends exceptional strength and longevity. These treatments ensure a surface hardness between HV900 and HV1050, greatly extending the operational lifespan and reducing maintenance requirements. Built to withstand challenging environments, our barrels deliver consistent performance for years.

FAQs of Twin Screw Barrel:

Q: How does the surface treatment enhance the lifespan of the Twin Screw Barrel?

A: The application of nitriding, hard chrome plating, or bimetallic coating increases surface hardness to HV900-1050, significantly improving resistance to wear and corrosion. This leads to an extended service life of 3 to 5 years depending on operating conditions.Q: What customizations are available for screw diameter and thread pitch?

A: Screw diameters can be tailored from 25 mm up to 180 mm, and thread pitch is fully customizable based on your extrusion process requirements. This allows for precise adaptation to specific application needs and materials.Q: When is it advisable to choose a bimetallic barrel inner liner over a nitrided one?

A: Bimetallic liners are recommended when processing highly abrasive or corrosive materials that demand additional resistance. Nitrided liners are suitable for standard operations with moderate wear demands.Q: Where can these Twin Screw Barrels be utilized?

A: Our barrels are designed for use in extrusion machinery for plastics, rubber, pelletizing, and compounding. They are ideal for manufacturers, exporters, and suppliers across diverse industries throughout India.Q: What is the manufacturing process for achieving the desired hardness and finish?

A: Each barrel undergoes precision machining followed by specialized surface treatmentsnitriding, hard chrome plating, or bimetallic coatingto reach the targeted hardness (HV900-1050), boosting strength and durability.Q: How does the cooling system benefit extrusion performance?

A: Our barrels can be equipped with either water or air cooling systems, which regulate temperature during the extrusion process. This ensures stable operation, consistent product quality, and prolongs component life.Q: What are the key benefits of using your Twin Screw Barrel in extrusion applications?

A: Major advantages include high strength, excellent wear and corrosion resistance, long service life, low operational noise, and broad customization. These attributes collectively improve productivity and reduce downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Twin Screw Barrel Category

Extruder Screw Barrel

Price Range 100000.00 - 150000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Corrosion resistance, High durability, Precision engineered

Material : Alloy Steel / Nitrided Steel

Color : Other, Polished Silver

Drive Type : Mechanical

|

VITAL FORCE ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |