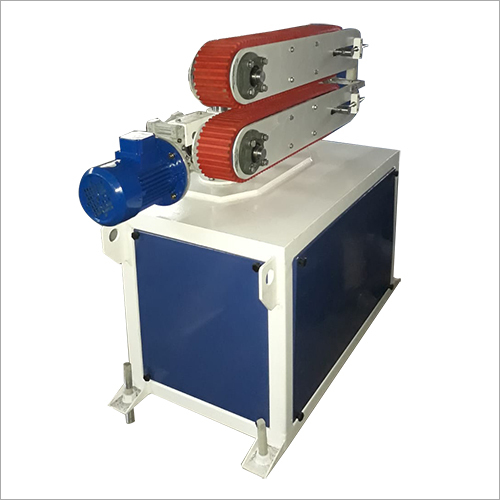

Most Popular Products

Extruder Screw Barrel

Extruder Screw Barrel Specification

- Tool Type

- Extruder Machine Spare

- Noise Level

- Low db

- Power Source

- Electric

- Spindle Speed

- Variable as per machine miles/hr

- Application

- Plastic Extrusion Machinery

- Product Type

- Extruder Screw Barrel

- Material

- Alloy Steel / Nitrided Steel

- Computerized

- No

- Automatic Grade

- Manual

- Drive Type

- Mechanical

- Voltage

- 220-440 V Volt (v)

- Weight (kg)

- Custom-as per order Metric Ton

- Dimension (L*W*H)

- Customizable Meter (m)

- Capacity

- Up to 500 Kg/hr Kg/hr

- Color

- Polished Silver

- OEM Service

- Available

- Surface Finish

- Polished / Hard Chrome Plated

- Barrel Type

- Single / Twin Parallel / Conical

- Heat Treatment

- Nitrided, Bimetallic on request

- Tolerance

- 0.01 mm

- Surface Hardness

- HV900-1000 (Nitrided)

- Suitable Polymers

- PVC, PE, PP, ABS, etc.

- Screw Diameter

- 20mm - 200mm

- Packaging

- Wooden Case / Standard Export Packing

- Screw Length

- Up to 6000mm

- Screw Design

- Single Flight, Double Flight, Special Profile

- Processing Type

- Machining, Grinding, Polishing

- Thread Pitch

- Customizable

Extruder Screw Barrel Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 5 Days

About Extruder Screw Barrel

Manufacturing plastic pipe with OFF-SPEC or biodegradable plastics can be challenging for extruder machines. When purchasing a new model, the best alternative is to pick one with an Extruder Screw Barrel since it permits the users to utilize a range of money-saving materials such as off spec or recycled plastic without compromising the quality and strength of an extruder machine. The provided Extruder Screw Barrel permit for maximum performance, resistance to fatigue, improved process control, and strength.

Versatile Customization

Our extruder screw barrels are designed to fit a wide array of plastic extrusion machinery. With options for single or twin barrel types, various screw designs, and precise customization in diameter, length, and thread pitch, we ensure compatibility and optimal performance across diverse industrial needs.

Superior Material & Finish

Manufactured from premium alloy or nitrided steel, these barrels undergo specialized machining, grinding, and polishing. The options for nitrided or bimetallic heat treatment and finishes such as hard chrome plating guarantee top-tier corrosion resistance, durability, and smooth operation during high-volume production.

Precision & Performance

Engineered with a keen focus on accuracy, each screw barrel maintains a tight dimensional tolerance of 0.01 mm and offers variable spindle speeds for low-noise, efficient extrusion. Their robust construction supports continuous production and ensures precise material processing for excellent end-products.

FAQs of Extruder Screw Barrel:

Q: How can I select the right type of extruder screw barrel for my application?

A: Consider your extrusion machinery requirements such as barrel type (Single, Twin Parallel, Conical), screw diameter (20200mm), and compatible polymers (PVC, PE, PP, ABS). Our team will guide you through the selection based on your process, materials, and capacity needs.Q: What is the manufacturing process for these extruder screw barrels?

A: The screw barrels are fabricated using high-grade alloy or nitrided steel, undergoing machining, grinding, and polishing. Heat treatments such as nitriding or bimetallic options on request enhance hardness and durability, with final surface finishes like hard chrome plating for optimal performance.Q: When should I consider ordering a customized screw design?

A: Custom screw designs are recommended when you have specific processing requirements, such as unique polymer blends, throughput rates, or particular extrusion profiles. We offer single flight, double flight, and special profile screws tailored to your operational demands.Q: Where are these screw barrels commonly used?

A: Our extruder screw barrels are widely used in plastic extrusion machinery across various industries, including manufacturers of pipes, profiles, sheets, and fittings utilizing polymers like PVC, PE, PP, and ABS.Q: What are the benefits of a nitrided or hard chrome plated surface?

A: Nitrided and hard chrome plated surfaces provide superior hardness (HV9001000), exceptional corrosion resistance, and reduced wear, resulting in prolonged barrel life and consistent production quality.Q: How does purchasing from your company ensure product quality?

A: We adhere to strict quality control, ensuring tight tolerances (0.01 mm) and using only high-grade materials. Our manufacturing processes guarantee precision engineering, durability, and compliance with industry standards, reinforced by secure packaging for safe delivery.Q: What is the typical packaging and shipping process for these products?

A: Extruder screw barrels are securely packed in wooden cases or standard export packaging to prevent damage during transit. We cater to both domestic and international clients, providing reliable and timely shipment worldwide.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Twin Screw Barrel Category

Twin Screw Barrel

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 50500 kg/hr

Color : Other, Metallic Grey/Silver

Control System : Other, PLC/Manual

Computerized : Yes

|

VITAL FORCE ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |