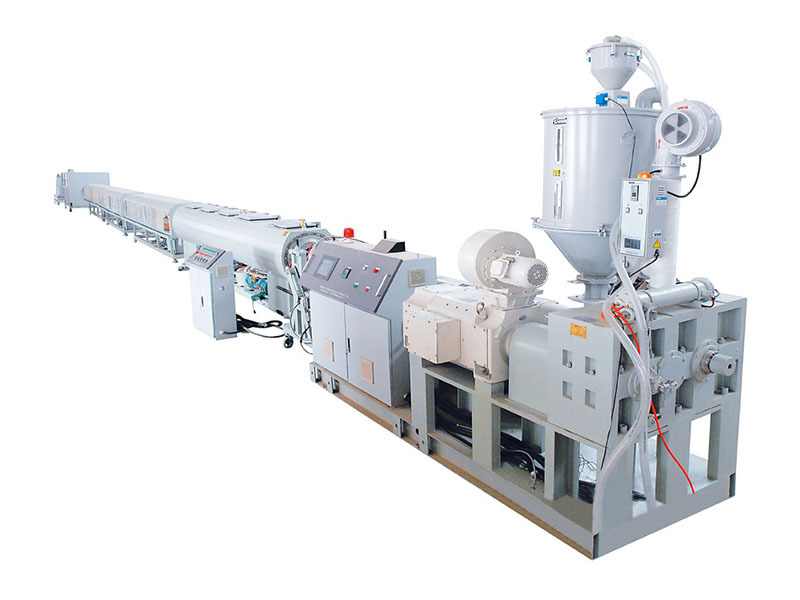

PVC Pipe Making Machine

PVC Pipe Making Machine Specification

- Welding

- High-frequency automatic welding

- Material

- Mild Steel with anti-corrosive coating

- Features

- Energy-efficient, Low maintenance, Digital control panel, High output rate

- Production Capacity

- 110 kg/h to 350 kg/h Kg/hr

- Voltage

- 380 V Volt (v)

- Usage & Applications

- Manufacturing of water supply pipes, drainage pipes, agricultural irrigation, and conduit pipes

- Pipe Diameter

- 16 mm to 315 mm Millimeter (mm)

- Pipe Thickness

- 0.5 mm to 15 mm Millimeter (mm)

- Automation Grade

- Automatic

- Linear Speed

- 1-10 m/min

- Roller Material

- High-grade Stainless Steel

- Frequency

- 50/60 Hz Hertz (HZ)

- Machine Weight

- Approx. 2500 kg Kilograms (kg)

- Motor Power

- 22 kW to 55 kW Kilowatt (kW)

- Dimension (L*W*H)

- 6500 x 1500 x 2200 mm Millimeter (mm)

- Pipe Material

- PVC (Polyvinyl Chloride)

- Noise Level

- < 75 dB db

- Length

- Customizable up to 6 meters Meter (m)

- Cooling System

- Water and air cooling combined

- Drive Type

- AC variable frequency drive (VFD)

- Barrel Heating Zones

- 4-6 zones

- Control System

- PLC (Programmable Logic Control)

- Feeding Type

- Automatic hopper feeder

- Screw Diameter

- 65/132 mm

- Cutter Type

- Fully automatic planetary cutter

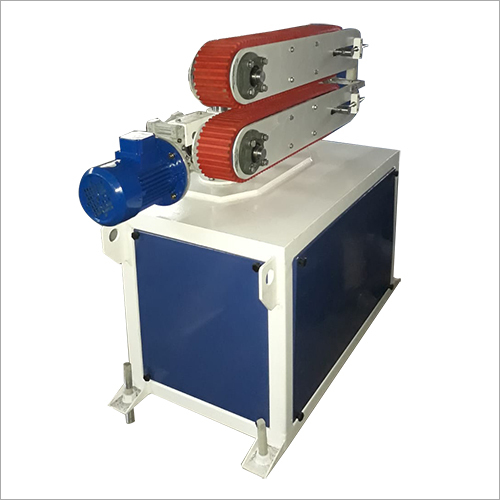

- Haul Off Unit

- Multi-claw haul-off with precision control

- Extruder Type

- Conical twin screw extruder

PVC Pipe Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- AHMEDABAD

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 1 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- WOODEN PACKAGING

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO

About PVC Pipe Making Machine

We are here manufacturing and supplying the PVC pipe making machine. The machine is automatic and easy to operate, the pipes made are of tough material that can be used for various purposes. The machine can be used for cutting and tilting purposes. The machine is very durable and has high speed in making pipes. The PVC pipes are used for water supply and other applications. The PVC Pipe making Machine has high strength and is safe for use.

Precision and Automation for Large-Scale Output

Designed with an automatic PLC-based control system, this machine offers continuous, automated operation and precision at every step. The multi-claw haul-off and fully automatic planetary cutter work in harmony to deliver consistent, high-quality PVC pipes, minimizing manual interventions and maximizing safety. You can reliably manufacture pipes tailored for various industrial and infrastructural needs, while reducing operational errors and labor costs.

Robust Construction and Energy Efficiency

This PVC pipe making equipment is built with mild steel, anti-corrosive coating, and stainless steel rollers to ensure longevity. The AC variable frequency drive (VFD) manages power efficiently, and the 22 kW to 55 kW motor range supports varied production demands. The machines energy-efficient design reduces electricity consumption, which means lower operating costs without compromising on the high output rate or quality.

Versatile Applications and Customization

Serving as a distributor, exporter, manufacturer, service provider, supplier, and trader in India, this machine meets multiple sectoral needsfrom water supply and agricultural irrigation to electrical conduit and drainage systems. With customizable pipe lengths of up to 6 meters and production capacities adjustable from 110 kg/h to 350 kg/h, it can adapt seamlessly to your unique project requirements.

FAQs of PVC Pipe Making Machine:

Q: How does the conical twin screw extruder improve PVC pipe production?

A: The conical twin screw extruder ensures uniform melting and efficient mixing of PVC material, resulting in consistent pipe quality, enhanced mechanical properties, and optimized energy use. This design is particularly effective for wide pipe diameter ranges and high output capacities.Q: What is the benefit of the PLC control system in this PVC pipe making machine?

A: The PLC (Programmable Logic Controller) system automates the entire production process, providing real-time monitoring, precise control of parameters, and easy adjustments, which leads to increased productivity, product consistency, and reduced risk of operational errors.Q: Where can this PVC pipe making machine be used effectively?

A: This machine is ideal for use in factories manufacturing water supply pipes, drainage pipes, agricultural irrigation pipes, and electrical conduit pipes across India and international markets. Its high output makes it suitable for both small-scale and large-scale production facilities.Q: What are the steps in the pipe manufacturing process with this machine?

A: The process begins with automatic feeding of PVC resin via the hopper, followed by melting and homogenization in the extruder. The pipe is then shaped, cooled by combined water-air systems, precisely pulled by the multi-claw haul-off, fully cut to length by the planetary cutter, and welded as required, ensuring seamless, high-quality pipes.Q: How does the fully automatic planetary cutter enhance efficiency?

A: The planetary cutter automatically adjusts to different pipe diameters and thicknesses, delivering precise and clean cuts without stopping the production line. This reduces downtime, increases throughput, and ensures each pipe meets strict dimensional tolerances.Q: What maintenance requirements can be expected for this machine?

A: Designed for low maintenance, the machine uses anti-corrosive materials and robust components. Routine checks on the extruder, cooling system, and cutters, along with periodic cleaning and lubrication, help ensure long operational life and minimize unexpected downtime.Q: What advantages does the combined water and air cooling system provide?

A: The dual cooling system rapidly stabilizes pipe dimensions and enhances surface finish during production, improving pipe strength and quality. It also allows for higher linear speeds and boosts overall manufacturing efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Pipe Making And Extrusion Machine Category

PVC Casing Pipe Machine

Price 750000 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Production Capacity : 40 to 80 kg/hrs

Pipe Material : PVC

Features : Single screw, stable output, easy operation, low maintenance

LLDPE Pipe Machine

Price 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Production Capacity : 50 kg/hr

Pipe Material : LLDPE

Features : Energy efficient, continuous operation, rapid changeover

HDPE Pipe Machine

Price 1650000 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Production Capacity : 50 120 kg/hr

Pipe Material : HDPE

Features : Consistent pipe thickness, energy efficient, durable construction, PLC control

Three Layer HDPE Pipe Machine

Price 5500000 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Automatic

Production Capacity : 250 to 450 kg/hrs

Pipe Material : HDPE

Features : Threelayer extrusion, high speed

|

VITAL FORCE ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |